Optimize & Adapt Solutions That Evolve With Your Operation

When volume shifts, workflows change, or product profiles evolve, Fidus helps you fine-tune, reconfigure, and integrate without overhauling your system. From control logic to WCS overlays, we help you scale with what you already have.

Your System Might Still Be Running — But It’s Holding You Back

Throughput Isn’t Budging |

Efficiency Keeps Dropping |

No Room to Adjust |

Small Changes. Big Payoffs.

We optimize your existing infrastructure unlocking new performance with smart, scalable adjustments across software, controls, and flow logic.

Throughput & Flow Tuning

Optimize routing, picking logic, merge control, and layout strategy.

Control Logic Adjustments

Update PLC and SCADA logic to align with shifting volume and workflows.

Pontem WCS Tuning

Adjust routing, priorities, and system behaviors — all without vendor lock-in.

Layout & Logic Redesign

Reconfigure conveyors and control points without major rebuilds.

Scalability Planning

Run simulations to identify bottlenecks and prioritize smart upgrades.

WMS / WCS Sync

Use Pontem as the middleware to align business logic and automation flow.

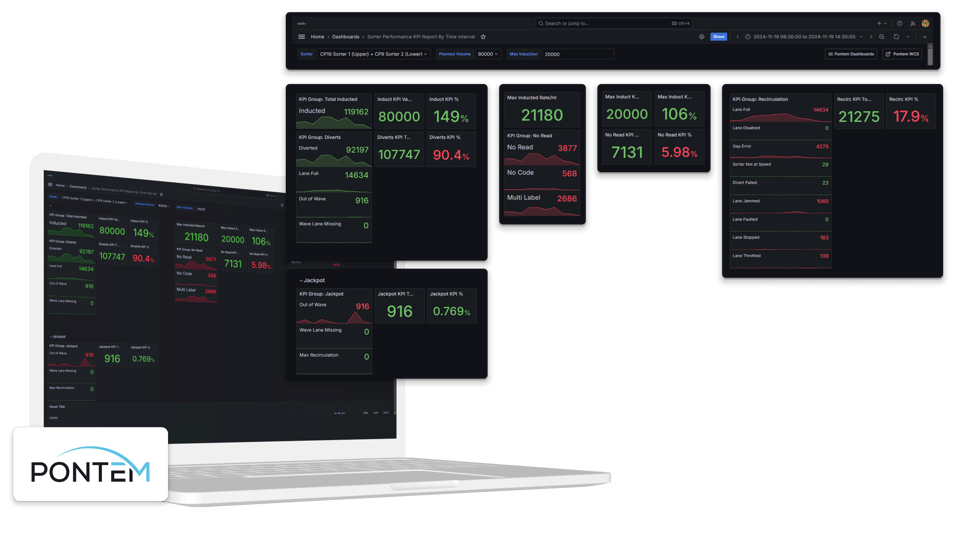

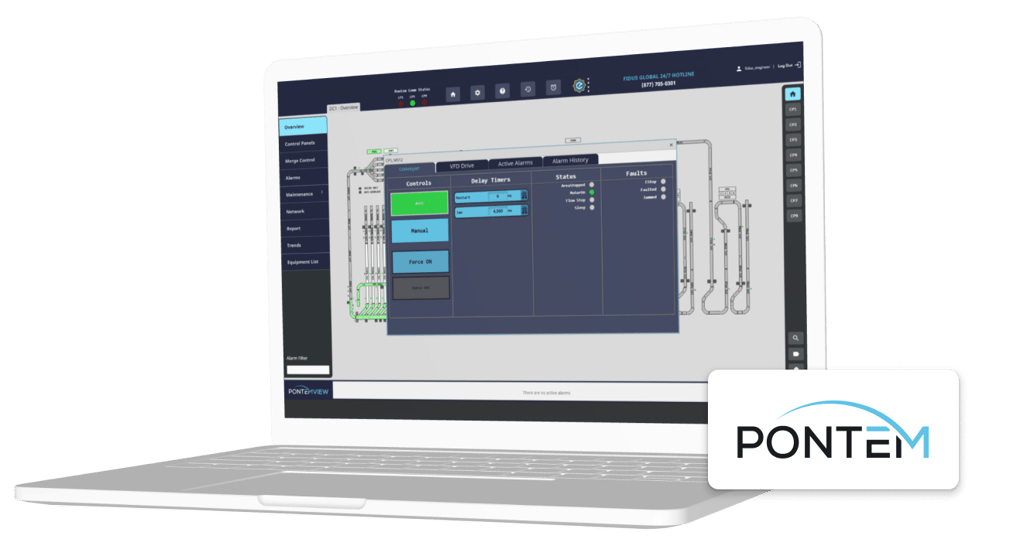

Pontem: Built For Control, Not Constraints

Pontem is Fidus’ award winning, open-architecture warehouse control system, the software layer that connects your automation, aligns your warehouse management system, and gives you back control. Designed to integrate with any vendor’s system, Pontem lets you adapt your workflows without vendor lock-in or costly recoding.

With Pontem, You Can...

Configure workflows, priorities, and routing without code rewrites or service tickets

Adjust sortation logic on the fly with flexible wave management features

Connect new hardware without change orders, using documented APIs

Visualize flow and performance in real time with Pontem View dashboards

Enable your team to act, not just observe, with role-based access and editable controls

Bridge WMS and MHE systems for better flow and fewer handoffs

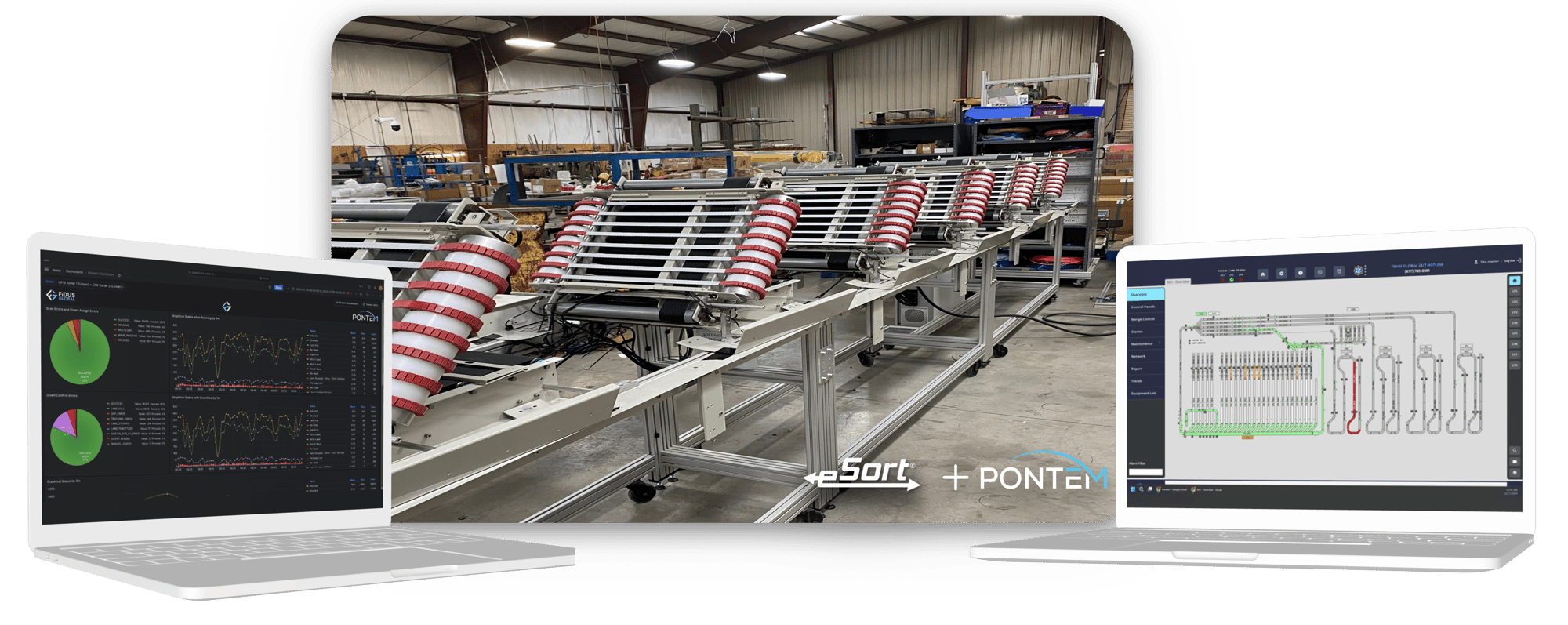

Pontem Bolt: Plug in at the Speed of Need

A lightweight version of our WCS, Pontem Bolt helps you quickly connect new hardware. Add scanners, print/apply stations, or diverters into live systems without change orders, long lead times, or vendor approval cycles.

How Pontem Bolt Works:

- Add hardware – from diverters to scanners to print/apply on your timeline, not your vendor’s

- Connect via Ethernet or Wi-Fi without rewriting logic or pausing production

- Respond rapidly to shifts in volume or product mix by reassigning flows or zones

- Avoid getting boxed into one provider’s roadmap — use the tools that fit your needs

- Avoid getting boxed into one provider’s roadmap by using the tools that fit your needs

%201.png?width=837&height=550&name=FG%20Pontem%20Bolt%20UC%20(1)%201.png)

eSort: More Throughput, No More Space Needed

eSort is a high-speed divert system you can install wherever you need it, even in underused corners of your warehouse. It runs on Pontem Bolt, integrates fast, and flexes with your demand.

- Installs anywhere

- Easy Integration

- Fast Adaptation to volume fluctuations

- Adapts with your volume

- Turnkey Deployment with Minimal install time

- Powered by Pontem Bolt – meaning no proprietary software lock-in

Plug in what’s missing. No rebuild needed.

Adding a weigh station? Print/apply? Scanner? Our system integrations help you connect and configure new equipment into your controls layer and Pontem logic without disrupting operations.

What You can Do:

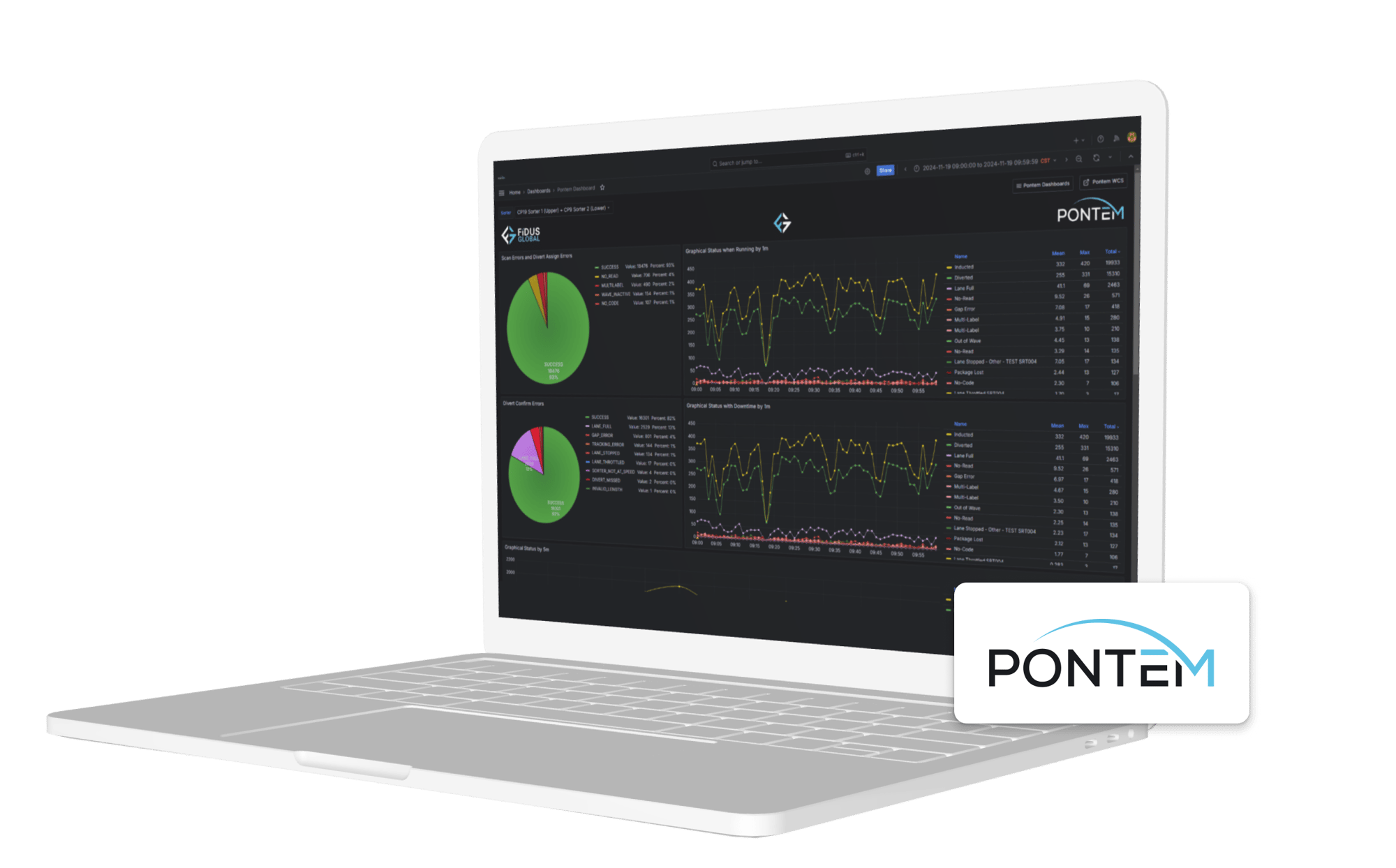

- Monitor throughput, routing logic, and asset performance in real time

- Spot system slowdowns before they affect SLAs

- Drill into root causes — not just symptoms — to drive permanent fixes

- Build dashboards and KPIs aligned to operations, IT, and engineering

- Use historical trends to plan smarter upgrades or labor shifts

Analytics & Diagnostics

See What's Happening – And Why

Fidus gives you more than just a dashboard. With Pontem View and SCADA integrations, you gain clear visibility into what’s working, what’s lagging, and where to intervene — before it turns into downtime.

What You can Do:

- Monitor throughput, routing logic, and asset performance in real time

- Spot system slowdowns before they affect SLAs

- Drill into root causes — not just symptoms — to drive permanent fixes

- Build dashboards and KPIs aligned to operations, IT, and engineering

- Use historical trends to plan smarter upgrades or labor shifts

Real-World Results Snapshot

Make the System You Have Work Harder

Let’s identify what’s slowing you down and turn it into a competitive edge with targeted software, control, and system upgrades

.png?width=817&height=505&name=Group%20183%20(2).png)